Vol 21, N° 42, Julio-Diciembre 2023

ISSN: 1409-3251, EISSN: 2215-5325

Technical efficiency analysis and profitability of local rice processing in Kwara state, Nigeria

Análisis de eficiencia técnica y rentabilidad del procesamiento local de arroz en el estado de Kwara, Nigeria

Sheu-Usman Oladipo AKANBI;

University of Ilorin, Nigeria

https://orcid.org/0009-0006-9940-5889

Oyetola Sunmibola OLANIYI

University of Ilorin, Nigeria

https://orcid.org/0009-0004-3897-7551

Adedayo Olufemi ADEKUNLE

University of Ilorin, Nigeria

https://orcid.org/0000-0002-9940-5889

Shehu Ahmad OLOHUNGBEBE

University of Abuja, Nigeria

Ahmad.olohungbebe@uniabuja.edu.ng

https://orcid.org/0000-0002-1646-7890

Bashir ALAO;

Agricultural and Rural Management Training Institute (ARMTI), Nigeria

https://orcid.org/0009-0006-1845-6120

DOI: http://doi.org/10.15359/prne.21-42.3

Fecha de recepción: 3/5/2023  Fecha de aceptación: 03/07/2023

Fecha de aceptación: 03/07/2023  Fecha de publicación: 25/07/2023

Fecha de publicación: 25/07/2023

|

Abstract The study seeks to assess the technical efficiency and profitability of local rice processing in Kwara state, Nigeria. The specific objectives are to: (a) estimate the cost and returns of local rice processing; (b) estimate the technical efficiency of the rice processing methods employed; (c) analyze the factors influencing technical efficiency of local rice processing; and (d) identify the constraints to local rice processing in the study area. A two-stage sampling technique was employed to select 120 processors who were randomly selected from a list of registered processors in Edu and Pategi Local Government Areas. The data were analyzed using descriptive statistics, gross margin, Data envelopment analysis and Tobit regression. Majority of the respondents were female (77.5%) and all the processors (100%) use traditional methods for all processing methods except for the milling and destoning stage. The Gross Margin and Capital turnover was estimated to be Note: $1 = N 430 Keywords: processors, efficiency, profitability |

Resumen El estudio busca evaluar la eficiencia técnica y la rentabilidad del procesamiento local de arroz en el estado de Kwara, Nigeria. Los objetivos específicos son: (a) estimar el costo y la rentabilidad del procesamiento local del arroz; (b) estimar la eficiencia técnica de los métodos de procesamiento de arroz empleados; (c) analizar los factores que inciden en la eficiencia técnica del procesamiento local del arroz; y (d) identificar las limitaciones para el procesamiento local de arroz en el área de estudio. Se empleó una técnica de muestreo de dos etapas para seleccionar 120 procesadores que fueron seleccionados al azar de una lista de procesadores registrados en las áreas de gobierno local de Edu y Pategi. Los datos fueron analizados mediante estadística descriptiva, margen bruto, análisis envolvente de datos y regresión Tobit. La mayoría de los encuestados eran mujeres (77,5 %) y todos los procesadores (100 %) utilizan métodos tradicionales para todos los sistemas de procesamiento excepto para la etapa de molienda y despedrado. El margen bruto y la rotación de capital se estimaron en Nota: $1 = N 430 Palabras claves: procesadores, eficiencia, rentabilidad |

Nigeria is the continent’s leading consumer of rice, one of the largest producers of rice in Africa and simultaneously one of the largest rice importers in the world. Rice is also an important food security crop; it is an essential cash crop for small-scale producers who commonly sell 80 percent of total production and consume only 20 percent (Food and agricultural Organization -FAO-, 2019).

Rice production generally in Nigeria is on the small-scale. The demand for rice among the population has not been met by local rice production. This, however, has created a gap between demand and supply and this has caused a shift to importation to meet the demand and local consumption in Nigeria (Oloyede et al., 2020). Farmers are growing rice on different production systems, they use upland, lowland or combined. This is dictated by the land available to them, expected yield, returns from the production, and the choice of varieties. Chidiebere-Mark et al., (2019) citing Stryker, showed that in sub-Saharan Africa (SSA), rice production has not increased in the real sense; the increase was only due to an extension of the area of land under cultivation. That is, productivity has not really changed. Rather, a sustainable increment in rice production should involve improved technology with ecosystems approach to achieve higher productivity, resource-use efficiency, and profitability. This will also lead to protection of environment. It has become imperative to meet the world’s food demand with this increasing population and at the least cost possible to achieve this. The major challenge faced by the processors in Nigeria is to identify the proper methods for premium rice processing (Ajala and Gana, 2015).

From the point of harvest till rice reaches the consumers table, rice passes through a wide range of unit operations which may have impact on the quantity and quality of the milled rice. However, rice agribusiness sector remains hesitant to invest in the rice value-chain, despite the recent policy intervention by the government. The policy intervention triggered an increase in the hectarage of land devoted to rice production but there has not been a noticeable improvement in the downstream value addition in the Nigerian rice industry (Amolegbe and Adewumi, 2016).

Rice processing including milling in Nigeria is very significant in agro processing sector; it is employing several thousands of parboilers, millers, and traders as demand is growing over the years now (Johnson and Masias, 2016). The processing involves several stages; from threshing of rice to removal of the husks, milling of the shelled paddy rice to removing the bran layer, then additional whitening stage to reach market standard. These processes generate several products which include the straws, the bran, the husks, and the milled rice grains itself (Schramm, 2006). Handling of harvested rice, processing, marketing, diseases and pest, soil management, irrigation water, harvesting methods and skills are some of the limitations facing rice production (Wilfred, 2006). Rice processing is facing constraints in Nigeria; they include inadequate improved rural infrastructures, inadequate credit accessibility, poor repair service and influx of sub-standard spare parts, high cost of power supply such as fuel and electricity, poor legal capacity, and inability to protect the owners’ rights of property, and poor policies implementation (Mohammed, 2019).

There are many potentials in rice cultivation, processing, local consumption as well as exportation. These potentials are there in exporting local (Ofada) rice to the Europe and the Americas. There are hundreds of thousands of Nigerians in abroad having potentials for demanding over 100 tonnes of local rice annually (Oyedepo and Adekanmbi, 2017). Akinniran and Faleye (2020) showed that rice production and processing could be profitable due to the increase in country’s rice demand which is being satisfied with rice importation. Comparing the paddy rice and milled rice marketing, Ebukiba and Ogbole (2020) asserted that paddy rice marketers have a higher profit margin than locally milled rice marketers. This is because the millers face poor government policies, high cost of transportation, poor grading and standardization problems, poor market information, as well as inadequate storage facilities and obsolete processing facilities. There has been an expansion indeed of both paddy rice and rice milling capacities. The possible increase in the quantity of standard quality rice that is being processed in Nigeria is about an additional 500,000 tonnes from the volumes in the previous years. This results into the increased share of premium rice quality to total production of about 27 %, from about 23 % in 2009 (Johnson and Masias, 2016).

There are many varieties of rice in Nigeria, some are good for Southern Nigeria, and some are good for northern Nigeria, while others are producing very well both in the north and in the south. Table 1 shows the various cultivars that are suitable for production in Northern Nigeria; there are about five varieties. These varieties mature earlier and produce significantly higher yields than the varieties which farmers in Northern Nigeria have been growing (Kamai, 2020). The study area is located in the Niger River valley; it has vast areas of lowland and many streams which make it possible to operate irrigation. Out of five varieties, only FARO 59 is suitable for upland area, others produce better under irrigation, and also thrive very well in shallow swampy area, except GAWAL R1 which thrives very well with irrigation and rainfed production system. GAWAL R1 that adapted well with both lowland and upland has the highest potential yield with 10 t/ha, while FARO 59 has the least potential yield of 3 t/ha, and the ligule type is intermediate in length. Other cultivars have better yield potential and they are long grain in nature.

Table 1: Some rice varieties commonly grown in Northern Nigeria

|

Variety |

Ecology |

Adaptation |

Tillering capacity |

Ligule type/ length |

Potential yield (t/ ha) |

|

FARO 44 |

Irrigated lowland |

Shallow swamp |

High |

Long grain |

7 |

|

FARO 52 |

Irrigated lowland |

Shallow swamp |

High |

Long grain |

6 |

|

FARO 61 |

Lowland |

Shallow swamp |

High |

Long grain |

5 |

|

FARO 59 |

Upland |

Rainfed upland |

Medium |

Intermediate |

3 |

|

GAWAL R1 |

Irrigated lowland |

Rainfed upland |

High |

Long grain |

10 |

Source: Guide to Rice Production in Northern Nigeria

Estimating efficiency is an essential issue in the use of scarce resources in production. This is so in the sense that it is the very first step to substantial resources savings (Balogun et al., 2018). Technical efficiency, cited by Farrell in Ebido et al. (2020), is the capability of an industry to produce a product for as much as possible with a specified available level of inputs using the available technology. Technical efficiency again compares the gaps in technical efficiency that could exist within firms, and differences in technical efficiency of many producers could be because of management decisions or firm specific features that can affect the usage of available technology properly by the producer (Abba and Abu, 2015). Efficient production could be achieved by reducing the resources meant for producing given products and/or maximizing products from available resources (Varian, 2014). Thus, to improve mills’ productivity, it requires that resources should be utilized efficiently with adequate attention paid to attaining production goals without any waste (Ebido et al., 2020).

However, local rice production including processing faces a lot of constrictions that are capable of leading to poor quality outputs, loss of value, reduced demand in the market and among the consumers, and loss of revenue. Such factors include lack of industrial drive due to poor government policy, high cost of production, poor market intelligence, poor grading, and standardization problems as well as inadequate storage facilities and obsolete processing facilities. These can kill the rice industry, impoverishing the rice farmers and the millers, and have negative effect on our national economy increasing importation of rice to meet local demand and reducing our gross domestic products (GDP). The milling factories are making efforts to manage these factors, yet the issues of inefficiency in rice production are still well pronounced, meaning that rice producing firms are producing below the optimum level. Some of them create efforts to increase their productions and improve their welfare. Repeatedly, the results of millers’ efforts within the industry are faded off by manifestation of these above-mentioned factors.

Hence, it is very vital to measure and know the technical efficiency of a farm and mill because it will enhance the optimum use of the scarce resources in production. This is often a matter policy. Understanding the technical efficiency /inefficiency for different crops and their processing with their determinants would have consequences on productivity and profitability of that industry. Understanding technical efficiency /inefficiency is extremely important for harnessing institutional support and providing proper and adequate resources to reinforce the millings’ profitability.

The quality of rice has become an important issue among Nigerian consumers who clearly show strong concern for imported rice, because of its quality in terms of cleanliness (West Africa Rice Development Association -WARDA-, 2015). The main objective of this paper is to assess the technical efficiency and profitability of local rice processing in Kwara state, Nigeria. The specific objectives are to: (i) estimate the cost and returns of local rice processing; (ii) estimate the technical efficiency of the rice processing methods employed; (iii) analyze the factors influencing technical efficiency of local rice processing; and (iv) identify constraints to local rice processing in the study area. We use survey data collected in 2021 from two Local Government Areas from the agricultural zone B. This study fills the existing gap of previous studies by focusing on the assessment of the economic activities of local rice processing in Kwara state. The result of this study is useful for policy formulation by government at all levels. It will serve also as a reference material to researchers and students alike.

The study was conducted in Kwara state, North Central part of Nigeria. Kwara state was formed on 27th May, 1967 along with other eleven states and it lies approximately on Latitude coordinates of 80 30’ and 80 50’ N and Longitude 40 20 and 40 35’ E. The state covers a total land area of 36,825 sq km. The state is bifurcated into 16 Local Government Areas (LGAs) under 4 Agricultural Zones (Kwara State Agricultural Development Project -KWADP-, 2019). Kwara state is bounded in the north by Niger State, in the south by Ekiti, Osun and Oyo states, in the east by Kogi state, and in the west by Benin Republic. Because of its strategic geographical location, Kwara is referred to as the gateway between the north and the southern part of the country (Ayinde, 2018).

Primary data was employed for this research. The main instruments for primary data collection were structured questionnaires and secondary information from sources such as lists of registered processors; journals, previous works, and publications were also used. The target population for the study are the rice processors. A 2-stage sampling method was adopted in collecting the data. The first stage involved the purposive selection of Edu and Pategi LGAs from the agricultural zone B because of their prominence in rice production;the second stage involved the random selection of sixty (60) processors each from the list of registered processors, culminating into a total of 120 processors.

Following the methodology adopted in a (Yusuf and Malomo, 2017) study, data collected was analyzed using descriptive statistics, gross margin, Data Envelopment Analysis (DEA) and mTobit regression model. Thus, this investigation intends to estimate the technical efficiency of local rice processors in Kwara state using DEA method and to identify the factors influencing technical efficiency of the processors in the study area.

Cost and returns were estimated with the use gross margin analysis.

Gross Margin = TR – TVC (1)

TR = Total revenue

TVC = Total variable cost

Data Envelopment Analysis

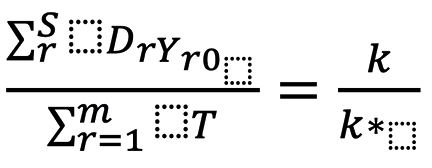

This is an analytical technique which seeks to estimate the technical efficiencies of the rice processors following (Basorun, 2013) methodology to generate technical efficiency scores of every sampled firm by using Data Envelopment Analysis (DEA) model; the overall approach is specified as:

Max TE =  (2)

(2)

Subject to: done

(3)

(3)

Where, j = 1,…. n; Dr Ti ≥ 0 , for any r, i ; r = 1,…..s; i = 1,…..m and Xij and Yrj individually are the amounts of the i-th input and r-th output of the j-th farm. Ti and Dr are input and output weights individually. As the relative magnitudes of the input and output amounts is maximized it would be limited to be no greater than one. The variables in the Data Envelopment Analysis model are described upon below:

Yrj = Quantity of Processed rice obtained by j-th processor measured in Kilogram/hectare (Kg).

Xij = Input quantity: Paddy rice (kg), Water (Litres), Labour in man day (Man days), Utilities e.g modern or olden source of energy (0=firewood; 1= diesel, electricity bills) and Modern implements usage (1 if used, 0, otherwise).

All the Decision-Making Units (DMUs) with a score of 1 were regarded as being technically efficient (fully or 100% efficient), while all other DMUs with scores of less than 1 or 100% were rated as being technically inefficient.

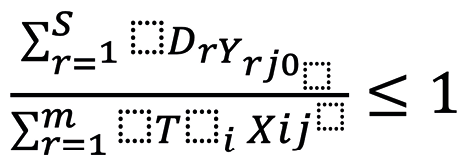

After generating the technical efficiency of every sampled processing unit by using DEA method, Tobit regression was used to estimate the factors influencing technical efficiency. Tobit regression model for this study is specified as follows:

(4)

(4)

Where Uj implies technical efficiency (TE) of processor, j is the technical efficiency score of processing unit ‘j. Β0, β1 are estimated parameters of efficiency factors,

Єj represent an error term of j processing unit which is presumed to be independent and normally distributed.

Socio-Economics Characteristics of Local Rice Processors in the Study Area

The result in Table 2 below shows that 77.5% of the respondents were female while 22.5% were male. This implies that females were more involved in rice processing activities than the male. This finding agrees with Ajala and Gana (2015) that women play active roles in the processing of agricultural produce.

Table 2 shows that more than half (50.8%) of the respondents fall within the age range of 41-50 years. The mean age of the respondents was 45 years. This means that the enterprise is dominated by the younger ones who are more active and stronger. This can be attributed to the fact that rice processing is tedious and laborious. The success or failure of rice processing depends largely upon how labour and other associated resources are utilized. Basorun (2013) in a study with rice production confirmed that young people within the age bracket 41-50 years dominate the enterprise.

Majority (57.5%) of the respondents had no formal education. This is in line with Babatunde (2019) result that stated that majority of the processors in the study area have no formal education. This is an indication that most of the processors are uneducated.

Result reveals that 63.33% had spent between 11-26 years in rice processing. This implies that many of the respondents had experience in local rice processing which seems to be a profitable enterprise in the study area, since there is a traditional belief that nobody will spend several years in an unprofitable venture. Majority (58.3%) of the respondents processed 101- 200 bags of rice. The average number of bags of rice processed in a month is 343 bags.

Table 2: Distribution of respondents according to socio-economic characteristics

|

Variables |

Frequency (n= 120) |

Percentage |

Mean |

|

Gender |

|

|

|

|

Male |

27 |

22.5 |

|

|

Female |

93 |

77.5 |

|

|

Age |

|

|

|

|

< 30 |

12 |

10.0 |

|

|

31-40 |

25 |

20.8 |

|

|

41-50 |

61 |

50.8 |

45 years |

|

Above 50 |

22 |

18.2 |

|

|

Marital status |

|

|

|

|

Single |

18 |

15.0 |

|

|

Married |

58 |

48.3 |

|

|

Divorced |

44 |

36.7 |

|

|

Widowed |

0 |

0 |

|

|

Household size |

|

|

|

|

< 3 |

16 |

13.3 |

|

|

4-6 |

36 |

30.0 |

|

|

Above 6 |

68 |

56.7 |

9 members |

|

Level of Education |

|

|

|

|

No formal education |

69 |

57.5 |

|

|

Primary education |

24 |

20.0 |

|

|

Secondary education |

17 |

14.2 |

|

|

Tertiary |

106 |

8.3 |

|

|

Processing Experience |

|

|

|

|

< 10 |

12 |

10 |

|

|

11 – 26 |

76 |

63.33 |

|

|

27-35 |

24 |

20 |

23 years |

|

≥36 |

8 |

6.67 |

|

|

Place of rice |

|

|

|

|

Major |

105 |

87.5 |

|

|

Minor |

15 |

12.5 |

|

|

Quantity produced (50kg per bag) |

|

|

|

|

≤100 |

20 |

16.7 |

|

|

101-200 |

70 |

58.3 |

|

|

201-400 |

12 |

10 |

343 bags |

|

401-800 |

16 |

13.3 |

|

|

801-1000 |

2 |

1.7 |

|

Source: Field survey, 2021

Mode of Operation Used for Rice Processing

The result in Table 3 reveals that all of the respondents used traditional methods of processing for the stages of soaking, threshing, winnowing, steaming, and drying; also, all the processors use modern method for milling while 65% of the processors uses traditional method and 35% uses modern methods for destoning. This implies that majority of the rice processing stages were carried out using traditional methods, this is in line with (Danbaba, 2019) result that stated that only milling is fully mechanized in Nigeria.

Table 3: Distribution of respondents according to mode of operation used for rice processing

|

Stages of Rice processing |

Mode of operation |

|

|

|

Traditional |

Modern |

|

|

|

Soaking |

|

|

Total |

|

Frequency |

120 |

0.0 |

120 |

|

Percentage |

100.0 |

0.0 |

100 |

|

Threshing |

|

|

Total |

|

Frequency |

120 |

100.0 |

120 |

|

Percentage |

100.0 |

0.0 |

100 |

|

Winnowing |

|

|

Total |

|

Frequency |

120 |

0 |

120 |

|

Percentage |

100.0 |

0.0 |

100 |

|

Steaming |

|

|

Total |

|

Frequency |

120 |

0 |

120 |

|

Percentage |

100.0 |

0.0 |

100 |

|

Drying |

|

|

Total |

|

Frequency |

120 |

0 |

120 |

|

Percentage |

100.0 |

0.0 |

100 |

|

Milling |

|

|

Total |

|

Frequency |

0 |

120 |

120 |

|

Percentage |

0.0 |

100.0 |

100 |

|

Destoning |

|

|

Total |

|

Frequency |

78 |

42 |

120 |

|

Percentage |

65 |

35 |

100 |

Source: Field survey, 2021

Analysis of Cost and Returns of Rice Processors

The result of costs, returns and profitability of local rice processing for processors is presented in Table 4. It was found that variable cost account for over 95% of the cost of processing for the processors and cost of paddy rice constituted the highest percentage of costs, accounting for 78.12% of processing, followed by the cost of milling and destoning rice and the least cost was incurred on packaging.

The gross margin (GM) of processors calculated was N142, 490. The rate of returns to processing was estimated at 55.33%, The capital turn over per bag of processed rice is 1.49; this implies that for every  1 invested in local rice processing, the processor gets

1 invested in local rice processing, the processor gets  1.49 as revenue and makes a profit of

1.49 as revenue and makes a profit of  0.49k. The profitability index of 0.49 shows that rice processing is a profitable enterprise for processors in the study area. The result is in line with the other studies (Inuwa et al, 2011; Ibitoye et al, 2014) that showed profitability index of rice processing to be positive.

0.49k. The profitability index of 0.49 shows that rice processing is a profitable enterprise for processors in the study area. The result is in line with the other studies (Inuwa et al, 2011; Ibitoye et al, 2014) that showed profitability index of rice processing to be positive.

Table 4: Analysis of cost and returns of local rice processors for 1 Tonne of processed rice

|

Items |

Average Value ( |

Percentage |

|

A. Total Revenue Sales of processed rice |

400,000 |

100.00 |

|

B. Variable cost Paddy cost |

210,000 |

78.12 |

|

Firewood |

1,850 |

0.69 |

|

Labour |

11,200 |

4.17 |

|

Water |

3,120 |

1.16 |

|

Cost of milling |

15,520 |

5.77 |

|

Cost of destoning |

13,820 |

5.14 |

|

Transportation |

1,400 |

0.52 |

|

Packaging |

600 |

0.22 |

|

Total variable cost (TVC) |

257,510 |

95.0 |

|

C. Fixed cost |

||

|

Total Fixed cost (TFC) |

550 |

0.02 |

|

Rent for storage |

8,425 |

1.31 |

|

Bowls & Cooking utensils |

1850 |

0.06 |

|

Tarpaulin/ Mats |

473 |

0.01 |

|

Tax |

11,298 |

1.40 |

|

D. Total Cost (TC) |

268,808 |

100.00 |

|

Gross Margin (TR – TVC) |

142,490 |

|

|

Rate of return (%) |

55.33 |

|

|

Capital Turnover |

1.49 |

|

|

Profitability index |

0.49 |

|

|

N.B; 1 tonne = 1000kg |

||

|

20 bags of 50kg of rice = 1000kg |

Source: Field survey, 2021

Technical and Scale Efficiency Measures of Local Rice Processors

The outcomes are illustrated on Table 5 below. On average, the local rice processors in the study area obtained a relatively low overall technical efficiency of 0.4965, pure technical efficiency of 0.8920, and scale efficiency of 0.5566. The result of overall technical efficiency score indicated that the processors could reduce their use of inputs by over 50% while still obtaining the same rice processing level. The result is supported by Miassi et al (2023) that stated that the technical efficiency rate obtained was 51% among the rice producers in Benin Republic. Specifically, the processors could improve their efficiency from 0.4965 to 0.8920 by reducing their scale inefficiency.

The scale efficiency of the studied rice processors was relatively low (0.5566) and most of them (91%) achieved a scale below 0.600 showing that most of these processors were operating below the optimal size.

Table 5: Summary of overall technical efficiency and pure technical efficiency

|

Summary 129732 |

Overall technical efficiency |

Pure technical efficiency |

Scale efficiency |

|

Mean |

0.4965 |

0.8920 |

0.5566 |

|

Std. deviation |

0.1070 |

0.1118 |

0.0236 |

|

Minimum |

0.1000 |

0.4320 |

0.2372 |

|

Maximum |

1.0000 |

1.0000 |

1.0000 |

|

Frequency distribution |

Percentage |

Percentage |

Percentage |

|

Less than 0.3 |

28.3 |

0.0 |

0.0 |

|

0.3- 0.6 |

47.5 |

29.5 |

91.0 |

|

0.6- 0.9 |

10.0 |

55.0 |

7.5 |

|

0.9- 1.0 |

14.2 |

15.5 |

1.5 |

|

Total |

100.0 |

100.0 |

100.0 |

Source: Field survey, 2021

Result of Tobit Regression Model

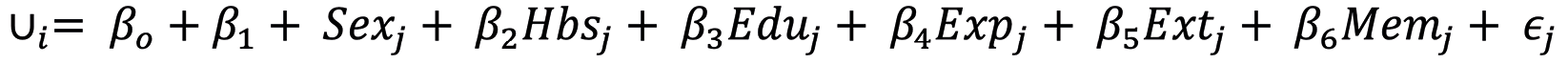

The result of the factors influencing efficiency of the rice processors is presented in Table 6 below. This was achieved using Tobit regression model. The R2 is 0.749 while the adjusted R2 is 0.788, which depicts that 74.9% of the dependent variable is being explained by the explanatory variables while the remaining 25.1% are due to factors outside those represented in the expression. The model has a good fit to the data. In the analysis, education, processing experience, modern implements, training and labour in the model were statistically significant at 5% and 10% level. Education level was significant at 10% level and had a positive influence on rice processing. This indicates that educational level of an individual can enhance their rate of adoption and use of modern equipment, thus increasing their level of output. The result is in line with the findings of Babatunde (2019). Years of processing experience was also significant at 10% level and was positive; this implies that processing experience can influence adoption and use of modern equipment, thus increasing output modern implement was significant at 5% level and was positively related, which implies that an increase in the adoption of modern implements will increase their efficiency of production. This is in tandem with the conclusion of Obianefo et al (2023). Training was also positively significant at 5% level, which implies that an increase in training for the processors will increase their processing efficiency. Labour was negatively significant at 5% level, which implies that a unit increase in labour cost will adversely increase the cost of production and lower processing efficiency of the rice processor.

Table 6: Tobit regression analysis showing the factors influencing rice processing efficiency

|

Processing efficiency |

Coefficient |

Standard errors |

T- stat |

p-value |

T-stat |

|

Constant |

4.004 |

3.936 |

1.017276 |

1.017 |

1.017 |

|

Age |

-0.114 |

0.297 |

-0.38384 |

-0.384 |

-0.384 |

|

Household size |

-0.230 |

0.230 |

-1.00000 |

-1.004 |

-1.004 |

|

Educational level |

0.740* |

0.136 |

5.441176 |

5.444 |

5.444 |

|

Processing experience |

0.144** |

0.139 |

1.035971 |

1.036 |

1.036 |

|

Modern implements |

0.048** |

0.429 |

0.111888 |

0.112 |

0.112 |

|

Utility |

-0.084 |

0.118 |

-0.71186 |

-0.712 |

-0.712 |

|

Water supply |

0.092 |

0.423 |

0.424908 |

0.218 |

0.218 |

|

Training |

0.116** |

0.273 |

0.683761 |

0.430 |

0.430 |

|

Labour |

0.080 |

0.117 |

0.683761 |

0.684 |

0.684 |

|

Membership |

-0.084** |

0.0194 |

-0.71186 |

-4.330 |

-4.330 |

Source: Field survey, 2021

Note: *,** indicates significance at 10%, 5% respectively

Ranking of Perceived Constraints to local rice processing

Table 7 shows that the sampled rice processors were faced with varied number of constraints on rice processing in the study area. Lack of loan facilities (Mean=2.79) was ranked first among the constraints associated with rice processing, next to high cost of equipment (Mean=2.53) ranked second, poor infrastructure was ranked third (Mean=2.29), lack of technical skills was ranked fourth (Mean=2.14), while lack of awareness was ranked fifth (Mean=2.00). The result implies that there were various constraints to rice processing in the study area and the disparity in the order of ranking may be due to difference in the level of their perception and experience of individual rice processor in the area.

Table 7: Distribution of respondents according to constraints to rice processing

|

Constraints |

Not severe |

Severe |

Moderately severe |

Strongly severe |

Mean |

Rank |

|

Inadequate loan facilities |

5 |

8 |

17 |

90 |

2.79 |

1st |

|

Poor infrastructure |

12 |

28 |

25 |

55 |

2.29 |

3rd |

|

Inadequate awareness |

10 |

44 |

21 |

45 |

2.00 |

5th |

|

Highcost of equipment |

7 |

16 |

20 |

47 |

2.35 |

2nd |

|

Poor technical skill |

10 |

28 |

43 |

49 |

2.14 |

4th |

Source: Field survey, 2021

Rice processing in the study area is profitable and the local rice processing firms are technically inefficient. Educational level, years of processing experience, use of modern implements, and training have positive effect on technical efficiency but labour cost is negatively impacted on rice processing. The implication of this study therefore is that the level of efficiency among the local rice processors in the study area could be raised from the current efficiency of 49.65% to an efficiency of 89.20% given the current level of technology if the available resources are efficiently utilized. Going by the empirical analysis of this study, the following policy options were recommended in improving the output of local rice processors in the study area: micro credit should be made available and accessible to rice processors. There is also a need for rice processors to maximally utilize resources to reduce inefficiency, thus sensitization on effective utilization of inputs, accessibility, and training on use of modern implements should be implemented. Modern processing machine should be made accessible to local processors with adequate and regular training on the technical know-how. It is also suggested that agencies involved in the construction of roads and provision of basic amenities like water and power supply should extend such to the communities where rice is produced. Rice processing is a profitable enterprise and females in the study area are largely involved, thus women should be encouraged to go into the enterprise and be given adequate training. This can be achieved by creating awareness through women association and cooperative society groups.

Abba, M.W. and Abu, H.M.I. (2015). Technical efficiency of small-scale rice production in Adamawa State, Nigeria. International Conference on Chemical, Food and Environment Engineering (ICCFEE’15), Jan. 11-12, 2015, Dubai (UAE).

Ajala, A.S. and Gana, A. (2015). Analysis of challenges facing rice processing in Nigeria. Journal of Food Processing, Article ID: 893673.

Akinniran T.N. and Faleye, G.R. (2020). Economics analysis of rice production and processing in Nigeria (1981 – 2019). International Journal of Agriculture, Environment and Bioresearch, 5(05): 113-132. https://doi.org/10.35410/IJAEB.2020.5557.

Amolegbe, K.B. and Adewumi, M.O. (2016). Value chain analysis of the rice industry in Nasarawa state, Nigeria. Gashua Journal of Irrigation and Desertification Studies 2(1), 1-20. https://www.semanticscholar.org/paper/VALUE-CHAIN-ANALYSIS-OF-THE-RICE-INDUSTRY-IN-STATE%2C-Amolegbe/9615b2caba2dfde1ba4588c3fac11bbacf4b1761.

Ayinde, O.E., Fatigun, O., Ogunbiyi, K., Ayinde, K., and Ambali, Y.O. (2018). Assessment of Central Bank intervention on rice production in Kwara State, Nigeria: A Case-study of Anchor Borrower’s Program. Proceeding of the International Conference of Agricultural Economists July 28-August 2 2018, Vancouver, Canada.

Babatunde, R.O., Omoniwa, A. and Aliyu, J. (2019). Post-harvest losses along the rice value chain in Kwara state, Nigeria: An assessment of magnitude and determinants. Cercetari Agronomice in Moldova, 2019.

Balogun, O.L., Adewuyi, S.A., Disu, O.R., Afodu, J.O. and Ayo-Bello, T.A. (2018). Profitability and technical efficiency of pineapple production in Ogun State, Nigeria. International Journal of Fruit Science, 18(4), 436-444. https://doi.org/10.1080/15538362.2018.1470594.

Basorun, J.O. (2013). Expository analysis of rice processing activities in Igbemo, rural Nigeria. American Journal of Social Issues and Humanities, 3(2), 79–81.

Chidiebere-Mark, N., Ohajianya, D., Obasi, P. and Onyeagocha, S. (2019). Profitability of rice production in different production systems in Ebonyi State, Nigeria. Open Agriculture, 4, 237–246.

Danbaba, N., Nkama, I., Badau, M.H., and Idakwo, P.Y. (2019). Influence of extrusion conditions on nutritional composition of rice-bamabara groundnut complementary foods. Arid Zone Journal of Engineering, Technology and Environment, 14, 559-582. http://www.azojete.com.ng.

Ebido, C.E., Okoli, T.O. and Ugwumba C.O. (2020). Technical efficiency and profitability of rice production in Anambra State, Nigeria. International Journal of Innovative Agriculture & Biology Research, 8(2), 29-39. www.seahipaj.org.

Ebukiba, E.S. and Ogbole, E.O. (2020). Profitability analysis of paddy and locally milled rice (oryza sativa L.) marketing in the Federal Capital Territory, Nigeria. European Journal of Agriculture and Food Sciences, 2(5), 1-5. http://dx.doi.org/10.24018/ejfood.2020.2.5.143.

Food and Agricultural Organization (FAO) (2019). The state of food and agriculture 2019. Moving forward on food loss and waste reduction. Rome. Licence: CC BY-NC-SA 3.0 IGO.

Ibitoye, S. J., Idoko, D. and Shaibu, U. M. (2014). Economic assessment of rice processing in Bassa local government area of Kogi state, Nigeria. Asian Journal of Basic and Applied Sciences, 1(2).

Inuwa, I.M.S., Kyiogwom, U.B., Ala, A.L., Maikasuwa, M.A. and Ibrahim, N.D. (2011). Profitability analysis of rice processing and marketing in Kano state, Nigeria. Nigerian Journal of Basic and Applied Science, 19(2), 293-298. http://www.ajol.info/index.php/njbas/index.

Johnson, M, and Masias, I. (2016). Assessing the state of the rice milling sector in Nigeria. The Nigeria Strategy Support Program (NSSP), working paper 40. International Food Policy Research Institute.

Kamai, N., Omoigui, L.O., Kamara, A.Y. and Ekeleme, F. (2020). Guide to Rice Production in Northern Nigeria. International Institute of Tropical Agriculture, Ibadan, Nigeria. 27.

Kwara State Agricultural Development Project (KWADP) (2019). List of Registered rice processors.

Miassi, Y. E., Akdemir, Ş., Dossa, K.F. and Omotayo, A.O. (2023). Technical efficiency and constraints related to rice production in West Africa: The case of Benin Republic. Cogent Food & Agriculture, 9, 1, https://doi.org/10.1080/23311932.2023.2191881.

Mohammed, U.A., Ibrahim, S., Hayatu, M. and Mohammed, F.A. (2019). Rice (Oryza Sativa L.) production in Nigeria: Challenges and prospects. Dutse Journal of Pure and Applied Sciences (DUJOPAS), 5(2b) 1-10.

Obianefo, C.A., Ezeano, I.C., Isibor, C.A. and Ahaneku, C.E. (2023). Technology gap efficiency of small-scale rice processors in Anambra state, Nigeria. Sustainability, 15, 4840. https://doi.org/10.3390/su15064840.

Oloyede, W.O., Muhammad-Lawal, A., Amolegbe K.B., Olaghere, I.L. and Joseph, I.A. (2020). Comparative analysis of the profitability of rice production systems in Kwara State, Nigeria, Agrosearch, 20(2), 82-101.

Oyedepo, E.O., and Adekanmbi, A.A. (2017). Profitability Analysis of Ofada Rice Production in Ogun State, Nigeria, Journal of Agricultural Science and Environment, 18(1 and 2), 97-106.

Schramm, R.C. (2006). Rice processing; milling and value-added effects. [M.S. thesis], Louisiana State University, Agricultural and Mechanical College, Baton Rouge, La, USA, 2006.

Varian, H.R. (2014). Big data: new tricks for econometrics. Journal of Economic Perspective, 28(2), 3-8.

West Africa Rice Development Association (WARDA) (2015). Annual Report. 2015: West Africa Rice.

Wilfred, O.R. (2006). Final survey report on the status of rice production, processing and marketing in Uganda. Japan International Cooperation Agency, Osaka, Japan, 2006.

Yusuf, S.A., and Malomo O. (2017). Technical efficiency of poultry egg production in Ogun state; A Data Envelopment Analysis (DEA) approach, Int J Poult sci., 6, 622-629.

Escuela de Ciencias Agrarias,

Universidad Nacional, Campus Omar Dengo

Apartado postal: 86-3000. Heredia, Costa Rica

Teléfono: (506) 2277-3569

Correo electrónico: ruralrev@una.cr

Equipo editorial

142,490 and 1.49 respectively. The processors achieved relatively low overall technical efficiency, pure technical efficiency, and scale efficiency score (0.4965 and 0.820 and 0.5566) respectively. Education level, years of processing experience, use of modern equipment and training on use of processing had positive effects on processing efficiency while labour cost showed negative influence on the rice processing efficiency. This study recommends that more attention should be paid to providing technical training and enhancing accessibility to modern equipment especially to the women processors.

142,490 and 1.49 respectively. The processors achieved relatively low overall technical efficiency, pure technical efficiency, and scale efficiency score (0.4965 and 0.820 and 0.5566) respectively. Education level, years of processing experience, use of modern equipment and training on use of processing had positive effects on processing efficiency while labour cost showed negative influence on the rice processing efficiency. This study recommends that more attention should be paid to providing technical training and enhancing accessibility to modern equipment especially to the women processors. 142 490 y 1,49 respectivamente. Los procesadores lograron una eficiencia técnica general relativamente baja, una eficiencia técnica pura y una puntuación de eficiencia de escala (0,4965 y 0,820 y 0,5566), respectivamente. El nivel educativo, los años de experiencia en el procesamiento, el uso de equipos modernos y la capacitación en el uso del procesamiento tuvieron un efecto positivo en la eficiencia de este, mientras que el costo de la mano de obra mostró una influencia negativa en la eficiencia del procesamiento del arroz. Este estudio recomienda que se preste más atención a brindar capacitación técnica y mejorar el acceso a implementos modernos, especialmente a las mujeres procesadoras.

142 490 y 1,49 respectivamente. Los procesadores lograron una eficiencia técnica general relativamente baja, una eficiencia técnica pura y una puntuación de eficiencia de escala (0,4965 y 0,820 y 0,5566), respectivamente. El nivel educativo, los años de experiencia en el procesamiento, el uso de equipos modernos y la capacitación en el uso del procesamiento tuvieron un efecto positivo en la eficiencia de este, mientras que el costo de la mano de obra mostró una influencia negativa en la eficiencia del procesamiento del arroz. Este estudio recomienda que se preste más atención a brindar capacitación técnica y mejorar el acceso a implementos modernos, especialmente a las mujeres procesadoras. )

)